Technology

Problem

Many alloys corrode merely from exposure to moisture and air, but the process can be strongly affected by exposure to certain substances as well. Corrosion can be concentrated locally to form a pit or crack, or it can extend across a wide area, more or less uniformly corroding the surface. Corrosion is widespread across consumer products, bridges, electric poles, roofs, canopies, etc.! It is also a challenge that many companies in water, mining, energy and processing industries face within their upstream, midstream, and downstream operations. Many plants suffer from severe corrosion in pipes and equipment, and the cost of replacement is significant. The existing maintenance, repair, and rehabilitation products/processes such as abrasive blasting & acid washing are characterized as expensive, labor-intensive, and reliant on toxic chemicals.

Our Solution

NanoTech provides an eco-friendly coating product which can be applied directly on corroded surfaces, with no or minimal surface preparation, to convert the existing rust to a protective anti-corrosion coating that prevents future corrosion and a primer. NanoTech's product significantly reduces labor requirements for surface preparation (no more abrasive blasting) and is more durable and longer lasting than existing solutions. This makes the treatment time short, and makes it possible to apply on difficult-to-access areas. The main ingredients of the product, which are extracted from bark, peel and roots of pomegranate plant, come with special physio-chemical structures that provide superior reaction efficiency.

Product Information

Unleashing the Power of Nanotechnology

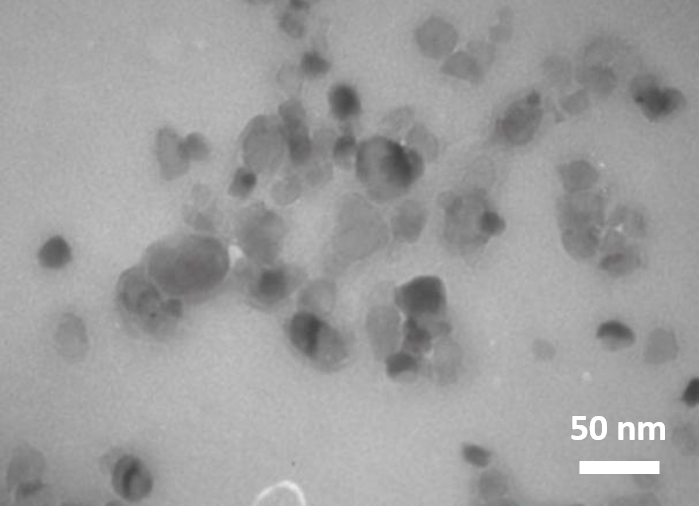

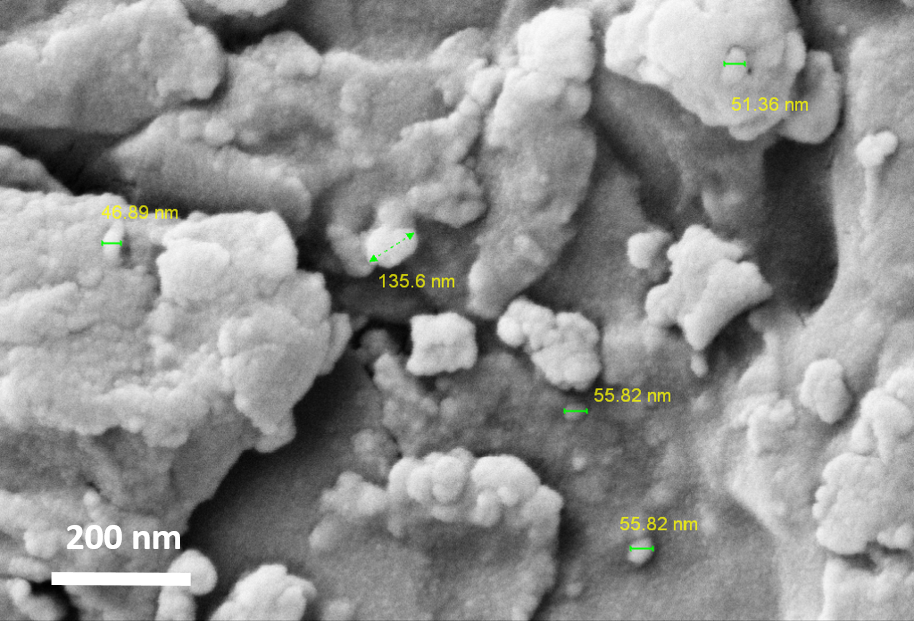

Characterization data obtained through SEM (Scanning Electron Microscopy) and TEM (Transmission Electron Microscopy) analyses confirm the nano-sized reactive particles in NanoTech’s water-based rust converter coating. The use of “specific” pomegranate plants as the source of our product’s main reactive ingredients ensures the material’s richness in polyphenols while maintaining a particle size in the nanometer range.

The significance of nano-sized particles in the rust converter coating lies in their ability to significantly impact the inhibition factor of the coating. Due to their small size, these particles enable the diffusion of reactants further into the rust, facilitating the conversion of a large portion of iron oxide, which enhances the coating’s inhibition efficiency and makes it less sensitive to the application method or the contamination grades of the rusty surface.

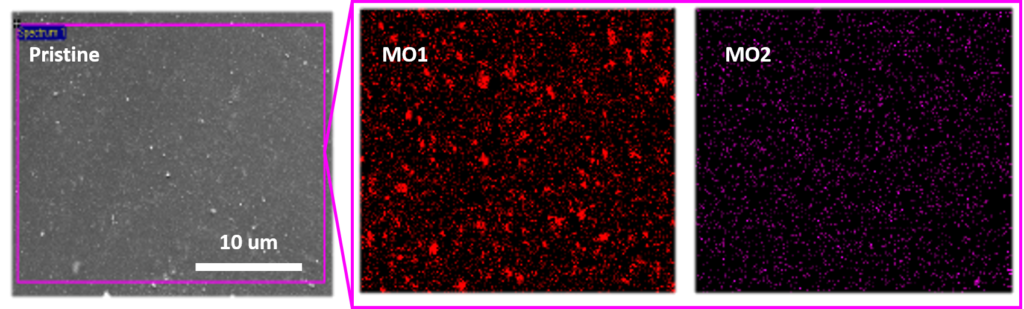

The incorporation of metal oxide nanoparticles (See EDX image below), in specific composition ratios and structures within NanoTech’s rust converter formulation serves multiple purposes. These nanoparticles function as molecular-corrosion inhibitors, enhancing the barrier effect of the coating by excluding the transport of aggressive species to the metal surface. Additionally, they act as binding agents that improve adhesion and stability properties of the finished coat.

Moreover, the incorporation of certain nano-particles improves the mechanical strength of the epoxy coating, providing additional anti-corrosion properties. They also contribute to cavity-filling and crack-bridging, preventing epoxy disaggregation during curing and resulting in a more homogenous coating. This leads to a reduced total free volume and an increase in the cross-linking density.

Environmental Advantages of Rust Conversion Technology

Choosing a sustainable rust-treatment method is not just a benefit, it is increasingly becoming a requirement. Our corrosion-mitigation solution reduces:

• Waste from abrasive blasting

• Use of harsh chemical solvents

• Pollution from airborne dust particles

• Labor and energy consumption

• Overall operational environmental footprint

How Our Rust Converter Supports Canadian Climate Challenges

Metal surfaces in Canada face extreme weather, moisture, and salt exposure - perfect conditions for corrosion. NanoTech Innovation’s rust-conversion technology is engineered specifically to withstand:

• West Coast humidity and salt air

• Northern freeze-thaw cycles

• Frequent rain and temperature swings

• Industrial and coastal environments

Our Competitive Advantage

Competitor 1

- NanoTechnology

- Low Cost

- Eco-friendly

- High durability

- Non-Hazardous

- Fast drying

Our Product

- NanoTechnology

- Low Cost

- Eco-friendly

- High durability

- Non-Hazardous

- Fast drying

competitor 2

- NanoTechnology

- Low Cost

- Eco-friendly

- High durability

- Non-Hazardous

- Fast drying

competitor 3

- NanoTechnology

- Low Cost

- Eco-friendly

- High durability

- Non-Hazardous

- Fast drying

Testimonials

What our clients say about us

“I enjoyed this product because it was very easy to use and I felt more at ease using it knowing that it’s non- toxic, and it smelled pretty good. It was also quite interesting to see the instant reaction that would take place and the little time it took for it to dry. Lastly, I was very satisfied with its quality considering how strongly the rust converter stuck to the surface of the vents.”

Painter on site

UBC maintenance project

“The Nanotech product is a cheaper alternative solution for the protection of facility metal and equipment. It has potential application scenarios for pressure piping, tank walls and vessel shell/heads. With minor preparation requirements (in lieu of sandblasting or acid washes), the product is recommended for future rust removal treatments. Its added corrosion resistance and non toxic nature further act as further reasoning to consider the use of the product.”

Asset Integrity Manager

Large Oil & Gas Company

1. How long does the rust converter take to cure?

Most applications cure within 24 hours under normal conditions, forming a stable primer layer that is ready for painting or sealing.

2. Can it be applied to rusted or bare metal?

Yes. It works on moderate to heavy rust and is also effective as a protective primer on clean or lightly oxidized metal surfaces.

3. Is abrasive blasting required before using the product?

No. Only loose and flaky rust needs to be removed. Full abrasive blasting is not required, which makes the process faster and cleaner.

4. Does the converted surface need additional coatings?

The treated surface forms a primer-like protective layer. For maximum durability, especially outdoors, applying a topcoat is recommended.

5. Is this product safe for indoor use?

Yes. It is formulated to be low-VOC and is safe for indoor applications when used with basic ventilation.